Learn How Slitter Rewinders Are Used In The Manufacturing Of Air and Water Filtration Systems.

In the complex process of creating an air or water filter, there are many pieces of industrial equipment and manufacturing stages that must be used, from injection molding of plastics to metal fabrication of intricate parts, but one of the most critical components is the membrane material itself.

This material is typically a type of filter paper or a polymeric cast material designed to allow particles of specific sizes to pass through creating incremental levels of filtration effects within the system. Without this membrane, the filter will not operate properly.

Filter paper or filter membrane is used in many applications such as air filters, air conditioners, fuel & oil filters, water filters, etc. Before any of these can be manufactured; however, the filter paper must be made.

The production of filter papers requires exacting specifications and tolerances. In this process, papers or other web-based materials such as non-wovens are created and wound onto large master rolls, some of these rolls can weigh several tons. Since there are many subsequent steps, the material must go through in the production of the finished filter, it is often required that the rolls be changed in size to fit different machines in that production process. Since these large “parent rolls” are typically too large to be used directly in the manufacturing process of the filters they must be slit into smaller more manageable sizes to fit the requirements of the specific manufacturing process of each type of filter.

The critical role of the Slitter Rewinder.

Machines called slitter rewinders have been in use for over 100 years, and is basic in nature. They take large rolls and make smaller ones, but in today’s hi-tech world the old clunky equipment of the past has evolved into high speed, high precision cutting machines. With modern materials and engineering, today’s slitters can run at speeds exceeding 500 meters per minute. That’s almost 22.5 Miles per hour. Examples of modern slitter rewinders can be seen here. https://www.elitecameron.com/slitter-rewinders

See a slitter rewinder in action below:

Often just called “slitters,” these machines process large rolls of material and unwind them through a series of rotating blades or static knives. These slitting blades cut the stuff into narrow widths then the material is rewound onto new cores creating several thinner width rolls from the larger and wider parent rolls. The slitter rewinder also has the ability to rewind any amount of the parent material thus forming a roll of any diameter smaller than the parent roll.

This ability to form finished rolls of exact dimensions required makes it possible to fabricate filters of different sizes.

One of the common ways to enable a much larger volume of gas or liquid to flow through a filter paper is pleating. Pleating requires the folding of Z shaped folds into a flat material which allows it to trap more particles along with an increased flow of the liquid or gas passing through the filter.

Without the ability to create rolled materials of specific sizes the pleating process would be much more complicated.

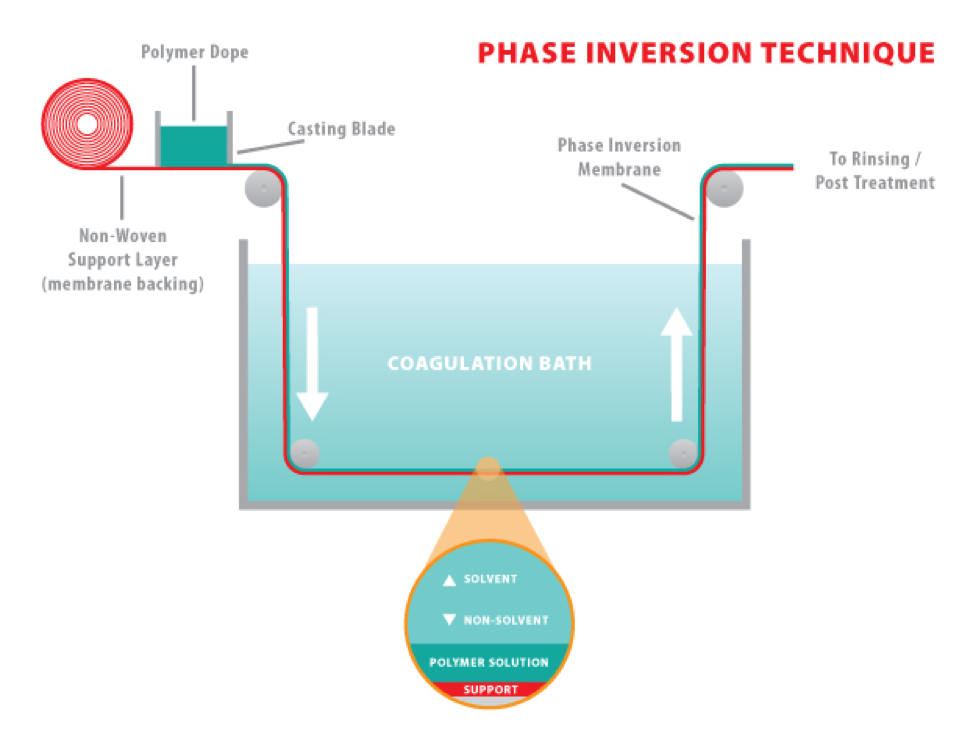

Slitter rewinders are even used indirectly in the manufacturing of polymer microfiltration membranes. As illustrated in this image from Snyder Filtration

{ Image: http://synderfiltration.com/2014/wp-content/uploads/2014/06/MF12-Phase-Inversion-Process.jpg Image Credit: Snyder Filtration}

Unlike a filter paper or fiber filter cloth, the polymer membranes use engineered polymers to create the filter membrane. But these need to be supported in the manufacturing process until they cure to form the finished material. In this case, chemicals are deposited onto a substrate or backing paper. This paper or non-woven material, much like what you would see on the backing of a sticker, serves as a support for the polymer. Slitter rewinders are used in the creation of these backing papers to ensure precise width tolerances.

Lastly, Slitter rewinders are used in the packaging of the filters. In the production of things like paperboard, cardboard, blown film, and foils. The plastic bags filters are packed in along with the boxes they ship and are stored in have all been touched in the manufacturing process by a slitter rewinder at some point.

Many industrial manufacturing processes employ the use of a slitter rewinder whether it be in the direct production of a product like a filter or indirectly in the packaging, storage, shipping and marketing of these types of products.